Novellini aluminium

Plus

Ductile

Easily workable and extrudable

depending on the design

Resistant

High mechanical characteristics

and resistant to corrosion

Light

Specific weight

1/3 of the steel

Natural

Natural origin,

non-toxic and non-magnetic

Evergreen

Totally recyclable

for an eco-sustainable use

Enviromentally friendly

Production processes and surface

finishes with low environmental impact

Foundry

Finding aluminium scraps

with incoming control activitiesMelting furnace

Production of aluminium billets

(25.000 tons per year)Chemical analysis of production

Aluminium alloys of normal production:

6060 / 6005 / 6082 / 3103

Other alloys on request

JOINT VENTURE NOVELLINI/MEC

Extrusion

Two internal extrusion lines

1800 tons presses each

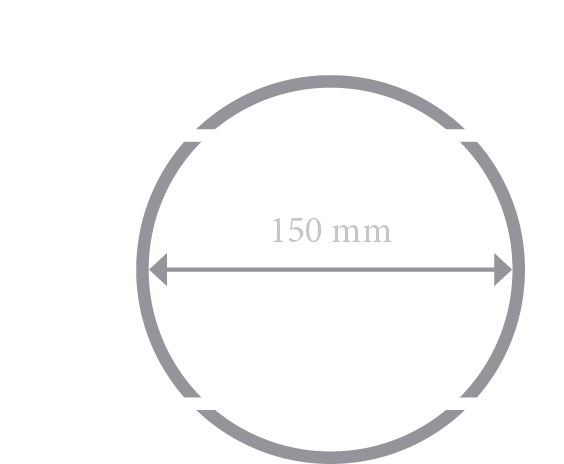

Extruded profiles up to 2.5 kg/m

Profiles greater than 2.5 Kg/m extrudable with consolidated long terms partners

Profile extrusion specifications on customer design

Extrusion with nitrogen to optimize and stabilize the process, allowing to improve the surface quality.

Chemichal tests to detect problems before the end of the finishing process.

In line dimensional control system to detect critical heights and operate immediately.

Machining

Novellini Industries dispose of a wide machineries inventory to cut and mechanical manufactoring of profiles.

It offers cutted and finished profiles for the customer needs.

Cut

Milling

Holing

Drilling

Shearing

Finishings

Powder coating

Dry painting process with epoxy powders that adhere to the profiles electrostatically, coating and protecting them.

Novellini Industries has integrated two vertical powder coating plants certificated QUALICOAT since 1999.

PAINTING SPECIFICATION

- vertical plant for 6,5 mt profiles just to be cutted

- vertical plant for 2,7 mt profiles finished before the paint coating

- pretreatment with chrome free organic passivation

- the paints are high quality epoxypolyester, high resistant to agents

The coating plants use low enviromental impact treatments, chrome free and close circuit, with the total recycle of the process water

- zero waste of the process water

- powder recycle 97%

Anodic oxidation

Electrochemical process where a protective oxide layer coats the surface and protects it from corrosion, guaranteed by consolidated partners

Available anodized finishings are

- matt chemical anodized Silver

- glossy chemical anodized Silver

- coloured and brillant anodized

PVD chrome plating

PVD chromium plating (physical vapor deposition) is the exclusive process of chrome plating of the Novellini Group aluminum

PVD allows to obtain good surface hardness, resistance to salt fog, corrosion and aggression from atmospheric agents, products for industrial use (solvents) and household products (various detergents and detergents).

Product non-toxicity and total absence of environmental impact of the

production cycle complete its fundamental characteristics.

Novellini PVD CHROME has been selected as a new ecological Process finishing in the Material ConneXion Library.